Product Description:

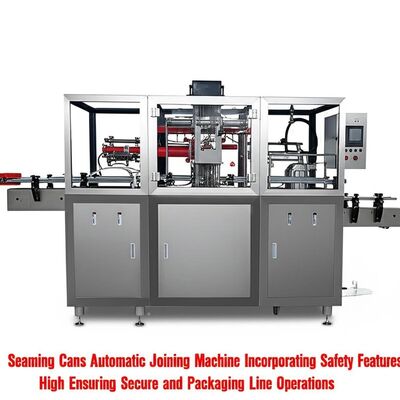

The Automatic Seamer Machine is a state-of-the-art solution designed to enhance the efficiency and reliability of sealing processes across various industries. This advanced piece of equipment is engineered as a semi-automatic machine, striking the perfect balance between automation and manual oversight to provide users with exceptional control and precision. At the heart of this machine lies a computerized control system that ensures seamless operation, allowing operators to easily program and monitor the sealing process for consistent and high-quality results.

One of the standout features of this Automatic Seam Making Machine is its impressive sealing speed. Capable of sealing a container in just 2 seconds, this machine significantly boosts productivity without compromising the integrity of the seal. This rapid sealing capability makes it an ideal choice for high-volume production environments where efficiency and turnaround time are critical. The swift operation also helps minimize downtime, enabling manufacturers to meet demanding deadlines with ease.

Safety is a paramount consideration in the design of this Automatic Sealing Device. Equipped with multiple safety features, including an emergency stop mechanism and robust safety guards, this machine prioritizes the well-being of its operators. The emergency stop function allows for immediate halting of the machine in case of any unforeseen issues, preventing accidents and damage. Additionally, the safety guards provide physical barriers that protect users from moving parts during operation, ensuring a secure working environment.

As an automatic type machine, this Automatic Seam Making Machine integrates advanced automation technology to streamline the sealing process. However, its semi-automatic automation type means that while many functions are automated, certain tasks still require human intervention, offering a flexible and adaptable approach to sealing operations. This hybrid automation model allows operators to maintain control over critical stages of the process while benefiting from the efficiency and consistency provided by automation.

The computerized control system is a core component that distinguishes this Automatic Sealing Device from traditional seaming machines. Through an intuitive interface, operators can easily adjust settings, monitor performance, and troubleshoot issues in real-time. This level of control not only enhances operational efficiency but also reduces the likelihood of errors, ensuring that each container is sealed perfectly every time. The system’s programmability also allows for quick changeovers between different container sizes and types, adding to the machine’s versatility.

In summary, the Automatic Seam Making Machine is a highly efficient, reliable, and safe solution for modern sealing needs. Its computerized control system, rapid sealing speed of 2 seconds per container, and comprehensive safety features make it an indispensable tool for manufacturers seeking to optimize their production lines. The combination of automatic machine type with semi-automatic automation provides a perfect blend of speed, precision, and operator involvement. Whether you are in the food and beverage industry, pharmaceuticals, cosmetics, or any other sector requiring secure container sealing, this Automatic Sealing Device stands out as a cutting-edge choice that delivers superior performance and peace of mind.

Technical Parameters:

|

Sealing Speed

|

2s/container

|

|

Seaming Quality

|

High

|

|

Sealing Type

|

Lid Sealing

|

|

Seam Quality

|

No Leakage

|

|

Machine Type

|

Automatic

|

|

Size

|

330*510*690mm

|

|

Safety Features

|

Emergency Stop, Safety Guards

|

|

Application

|

Seaming Cans, Jars, And Containers

|

|

Dimensions

|

1200 Mm X 800 Mm X 1500 Mm

|

|

Automation Type

|

Semi-Automatic

|

Applications:

The ShengMing SM-003YF Automatic Seam Forming Machine is an advanced solution designed for various industrial and manufacturing applications where precision and efficiency are paramount. This fully automatic seaming device excels in providing high-quality, no-leakage seams on cans with diameters ranging from 45mm to 130mm, making it ideal for the food, beverage, pharmaceutical, and chemical industries. Its computerized control system ensures consistent and reliable operation, minimizing human error and maximizing productivity.

In production environments requiring continuous and high-speed can sealing, the ShengMing SM-003YF Automatic Joining Machine is the perfect fit. Its compact size (330*510*690mm) and export-standard carton packaging make it easy to integrate into existing production lines and convenient to transport and install. Certified with CE, this machine guarantees safety and compliance with international standards, providing peace of mind for manufacturers.

The Automatic Sealing Device is especially suitable for medium to large scale factories where precision seam quality is a must to prevent leakage and maintain product integrity. Its fully automated operation mode reduces labor costs and enhances operational efficiency, while the computerized control system allows for easy adjustment and monitoring of the sealing process. With a supply capacity of 200PCS per month and a prompt delivery time of 15 days, ShengMing ensures that production schedules are met without delay.

This machine is essential for applications including canned food production, beverage canning, chemical container sealing, and pharmaceutical packaging, where airtight and durable seams are critical. The ShengMing SM-003YF supports payment flexibility through L/C and T/T terms and requires a minimum order quantity of 100PCS at a competitive price of US$460 each, making it an excellent investment for manufacturers seeking to improve their packaging line efficiency.

Overall, the ShengMing SM-003YF Automatic Seam Forming Machine is a reliable, efficient, and certified solution that meets the demands of modern industrial sealing needs, ensuring superior seam quality and operational convenience in a wide range of application occasions and scenarios.

Customization:

ShengMing presents the SM-003YF Automatic Seam Forming Machine, a semi-automatic solution designed to meet high standards of seaming quality with no leakage. Certified by CE, this Automatic Seaming Machine is ideal for cans with diameters ranging from 45 to 130mm, ensuring precise and reliable sealing every time.

With dimensions of 1200 mm x 800 mm x 1500 mm, the Automatic Sealing Device is compact yet powerful, capable of handling a supply ability of 200PCS per month. The minimum order quantity is 100PCS, priced competitively at US$460 each.

Packaging is carefully done in export carton packages measuring 330*510*690mm to ensure safe delivery. The delivery time is approximately 15 days, with flexible payment terms including L/C and T/T.

Choose the ShengMing SM-003YF Automatic Seam Forming Machine for high-quality, efficient, and reliable sealing solutions that enhance your production line's performance.

Support and Services:

Our Automatic Seamer Machine is designed to provide reliable and efficient sealing solutions for a wide range of container types. To ensure optimal performance and longevity of the machine, we offer comprehensive technical support and services.

Technical Support:

Our team of experienced technicians is available to assist with installation, setup, and troubleshooting of the Automatic Seamer Machine. We provide detailed user manuals and operation guides to help you understand the machine's functions and maintenance requirements. Remote support is also available to diagnose and resolve issues promptly.

Maintenance Services:

Regular maintenance is crucial for the smooth operation of the Automatic Seamer Machine. We offer scheduled maintenance services, including inspection, cleaning, lubrication, and part replacement. Our maintenance plans are designed to minimize downtime and extend the machine's lifespan.

Training:

We provide comprehensive training programs for operators and maintenance personnel to ensure safe and efficient use of the Automatic Seamer Machine. Training can be conducted on-site or remotely, covering machine operation, safety protocols, and basic troubleshooting techniques.

Spare Parts and Upgrades:

Genuine spare parts are available to maintain the machine’s performance and reliability. We also offer upgrade options to enhance the machine’s capabilities, including software updates and hardware improvements.

Warranty and Service Agreements:

The Automatic Seamer Machine comes with a standard warranty covering manufacturing defects and performance issues. Extended service agreements are available for additional coverage and priority support.

For any technical support or service needs, please refer to the provided user manual or contact our support team through the official channels.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!